Article Plan: Free Small Engine Repair Course PDF

Discover comprehensive resources for free small engine repair training! This guide details PDF courses, online tutorials, and manuals for engine maintenance and troubleshooting.

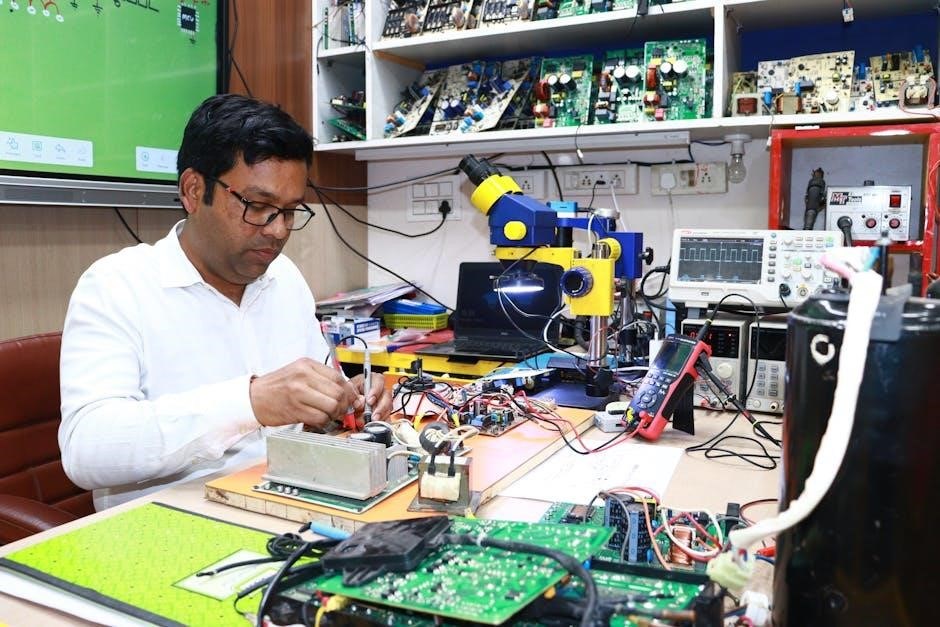

Embarking on small engine repair doesn’t require expensive schooling! A wealth of free resources, particularly PDF courses, empowers enthusiasts and DIYers to master essential skills. This article unveils pathways to acquiring knowledge for maintaining and fixing common small engines – those powering lawnmowers, generators, and more.

We’ll explore readily available PDF guides, online tutorials, and manufacturer resources. These materials cover everything from basic maintenance to complex troubleshooting. Learning to repair these engines saves money, promotes self-sufficiency, and extends the life of valuable equipment. This guide focuses on accessing quality, free information to kickstart your repair journey, offering a practical alternative to costly formal training.

What are Small Engines?

Small engines are typically defined as internal combustion engines producing fewer than 25 horsepower. They power a vast array of equipment, from everyday tools like lawnmowers and chainsaws to more specialized machinery like generators and pressure washers. These engines are commonly two-stroke or four-stroke designs, differing in their operational cycles and complexity.

Understanding their fundamental components – the carburetor, ignition system, and fuel system – is crucial for effective repair. While seemingly simple, small engines require precise maintenance and troubleshooting. A free repair course PDF will often begin with a detailed overview of these engine types and their core functionalities, providing a solid foundation for learning.

Why Learn Small Engine Repair?

Learning small engine repair offers significant benefits, primarily substantial cost savings. Instead of replacing broken equipment, you can diagnose and fix issues yourself, avoiding expensive service fees. Furthermore, it fosters self-reliance and problem-solving skills, empowering you to maintain your tools and machinery.

A free small engine repair course PDF provides accessible training, allowing you to learn at your own pace. This knowledge is valuable for homeowners, farmers, and anyone relying on outdoor power equipment. Mastering these skills can even open doors to potential side hustles or entrepreneurial ventures, offering repair services to others.

The Benefits of a Free PDF Course

A free Small Engine Repair Course PDF offers unparalleled accessibility and convenience. You can study anytime, anywhere, without the constraints of a fixed schedule or classroom setting. These resources often cover fundamental principles, common repairs, and troubleshooting techniques, providing a solid foundation.

PDF formats are easily downloadable and storable, creating a readily available reference library. They eliminate the need for expensive textbooks or enrollment fees, making education affordable for everyone. Moreover, many PDF courses supplement learning with links to helpful videos and online resources, enhancing comprehension and practical application.

Finding Free Small Engine Repair Courses

Locating free small engine repair courses requires strategic searching. Start with a targeted Google search using keywords like “free small engine repair PDF,” “online engine repair course,” or “DIY engine repair guide.” Explore educational platforms like Skillshare and Udemy, filtering for free options.

Manufacturer websites, such as Briggs & Stratton and Tecumseh, frequently offer downloadable manuals and service guides. Don’t overlook online forums dedicated to small engine repair; members often share valuable resources and PDF documents. Remember to verify the source’s credibility before relying on the information provided.

Online Resources for Free PDFs

Numerous websites compile free PDF resources for small engine repair. ManualsLib and RepairManualsNow are excellent starting points, offering a vast library of service manuals. Tradebit and similar platforms sometimes provide free previews or downloadable sections of repair guides. Archive.org, the Internet Archive, can contain digitized versions of older manuals.

Always exercise caution when downloading PDFs from unfamiliar sources; scan files for viruses. Look for reputable sites with clear download instructions and user reviews. Consider joining online communities where members share links to verified free resources, ensuring a safer and more reliable experience.

YouTube Channels Offering Repair Tutorials

YouTube is a treasure trove of free small engine repair tutorials. Donny’s Tech Tips provides detailed, step-by-step guides for various engine types. RepairClinic offers a comprehensive library of repair videos, including diagnostics and part replacement. Outdoor Power Info focuses on lawnmowers and other outdoor equipment, with practical repair advice.

Search specifically for your engine brand and model number for targeted results. Remember to prioritize channels with clear visuals, concise explanations, and positive user feedback. Supplement video tutorials with service manuals for a complete understanding of the repair process.

Manufacturer Websites & Free Manuals

Directly accessing manufacturer websites is a prime source for free repair manuals. Briggs & Stratton and Honda both offer extensive online databases of service manuals, parts lists, and troubleshooting guides. Tecumseh, while older, often has manuals available through third-party archives linked from enthusiast sites.

Typically, you’ll need the engine model number to locate the correct manual. These manuals provide detailed diagrams, repair procedures, and safety information. Downloading and saving these PDFs ensures access even without an internet connection, creating a valuable personal repair library.

Essential Tools for Small Engine Repair

Successfully tackling small engine repairs requires a basic toolkit. Essential hand tools include socket sets, wrenches (both open-end and box-end), screwdrivers (Phillips and flathead), pliers, and a torque wrench. Diagnostic tools like a multimeter are crucial for electrical system checks, while a compression tester assesses engine health.

Safety equipment is paramount: wear safety glasses, gloves, and consider ear protection. Investing in a good quality toolset will save time and frustration. Remember, having the right tools makes even complex repairs manageable, complementing your free course knowledge.

Basic Hand Tools

A solid foundation for small engine repair begins with fundamental hand tools. Essential items include a comprehensive socket set covering common bolt sizes, adjustable wrenches for versatility, and a selection of screwdrivers – both Phillips and flathead – for various fasteners. Pliers (slip-joint, needle-nose, and locking) are invaluable for gripping and manipulating parts.

Don’t forget a rubber mallet for gentle persuasion, and a set of feeler gauges for precise gap measurements. Quality matters; investing in durable tools ensures longevity and prevents damage. These basic tools, combined with a free repair course, empower you to handle most common maintenance tasks.

Diagnostic Tools

Beyond basic hand tools, accurate diagnosis requires specialized equipment. A multimeter is crucial for testing electrical components like ignition coils and sensors, verifying voltage and continuity. A compression tester assesses cylinder health, revealing potential issues with rings or valves. Spark testers quickly confirm ignition system functionality.

Fuel pressure gauges help pinpoint carburetor or fuel pump problems. While more advanced tools exist, these provide a strong starting point. Combining these diagnostic tools with knowledge gained from a free repair course allows for efficient and accurate troubleshooting, saving time and money on repairs.

Safety Equipment

Prioritizing safety is paramount when working on small engines. Always wear safety glasses to protect your eyes from debris and chemicals. Oil-resistant gloves shield your hands from burns and harsh fluids. A well-ventilated workspace is essential, as engines produce carbon monoxide.

Consider a respirator when dealing with carburetor cleaning or painting. Sturdy footwear prevents injuries from dropped tools. A fire extinguisher rated for flammable liquids should be readily accessible. Remember, a free repair course emphasizes safe practices alongside technical skills, ensuring a secure working environment.

Common Small Engine Problems & Solutions

Free repair courses often cover frequent issues. Carburetor problems, like flooding or lean mixtures, are common; cleaning or rebuilding the carburetor usually resolves them. Ignition failures, often due to faulty spark plugs or coils, require replacement. Fuel system issues, including clogged fuel lines or filters, necessitate cleaning or replacement.

A good course will demonstrate troubleshooting techniques. Understanding these common problems empowers you to diagnose and fix issues independently. Many PDF resources detail step-by-step solutions, making repairs accessible even without professional experience. Remember to consult manuals for specific engine models.

Carburetor Issues

Free small engine repair courses dedicate significant time to carburetor troubleshooting. Common problems include a clogged carburetor, a faulty float, or incorrect fuel mixture settings. Symptoms often manifest as hard starting, rough idling, or a lack of power. PDF guides frequently detail carburetor disassembly, cleaning, and reassembly procedures.

Learning to identify and address these issues is crucial. Many courses emphasize the importance of using carburetor cleaner and compressed air. Understanding the function of each carburetor component, as explained in free manuals, is key to successful repair. Proper adjustment ensures optimal engine performance.

Ignition System Failures

Free small engine repair courses cover ignition system diagnostics extensively. Common failures include a faulty spark plug, a defective ignition coil, or a malfunctioning magneto. Symptoms often present as a no-start condition or intermittent engine misfires. PDF resources illustrate testing procedures using multimeters and spark testers.

Courses highlight the importance of checking the air gap between the ignition coil and the flywheel. Understanding timing and points adjustment (in older engines) is vital. Free manuals provide detailed wiring diagrams for troubleshooting. Replacing worn or damaged components restores reliable ignition and engine operation.

Fuel System Problems

Free small engine repair courses dedicate significant attention to fuel system issues. Common problems include clogged fuel filters, a dirty carburetor, and a failing fuel pump. Symptoms manifest as hard starting, rough idling, or a complete lack of power. PDF guides demonstrate carburetor disassembly and cleaning techniques.

Courses emphasize the importance of using fresh fuel and fuel stabilizer. Learning to diagnose fuel delivery issues with a fuel pressure tester is crucial. Free manuals often include diagrams of the fuel system components. Replacing deteriorated fuel lines and rebuilding carburetors restores optimal engine performance.

Understanding Small Engine Repair Manuals

Free small engine repair courses highlight the vital role of repair manuals. These PDF documents are the cornerstone of successful troubleshooting. Courses teach how to locate and utilize these resources effectively. Manuals contain detailed exploded views, parts lists, and step-by-step repair procedures.

Understanding the organization of a manual is key; sections typically cover safety, specifications, and repair instructions. Free guides emphasize deciphering diagrams and interpreting technical terminology. Learning to identify part numbers and torque specifications prevents damage. Proper manual usage ensures safe and accurate repairs.

Decoding Manual Diagrams

Free small engine repair course PDFs stress the importance of diagram interpretation. Manuals utilize exploded views, showcasing component relationships. Learning to identify parts within these diagrams is crucial for disassembly and reassembly. Courses often dedicate sections to understanding line types and symbols.

Effective decoding involves recognizing how parts connect and interact. Understanding numbering systems links diagrams to parts lists. Free resources highlight common diagram conventions. Mastering this skill minimizes errors during repairs. Visualizing the engine’s internal structure through diagrams enhances troubleshooting efficiency and prevents costly mistakes.

Safety Precautions in Manuals

Free small engine repair course PDFs consistently emphasize safety. Manuals detail critical precautions, including disconnecting the spark plug to prevent accidental starting. Proper ventilation is highlighted when working with fuels and exhaust. Courses reinforce the use of safety glasses and gloves during all repair procedures.

Understanding fuel handling protocols is paramount, avoiding spills and open flames. Manuals warn against hot engine components, requiring cooling periods before work. Free resources stress the importance of a clean, organized workspace. Adhering to these guidelines minimizes risks and ensures a safe repair environment.

Troubleshooting Guides within Manuals

Free small engine repair course PDFs often include detailed troubleshooting sections. These guides systematically address common issues, like starting problems or poor performance. Manuals present charts outlining potential causes and solutions, simplifying diagnostics. Users learn to identify symptoms – such as unusual noises or smoke – to pinpoint the problem.

Step-by-step instructions guide through testing components, like the carburetor or ignition system. Free resources emphasize a logical approach, eliminating guesswork. These guides often include diagrams illustrating component locations and testing procedures. Effective troubleshooting minimizes repair time and costs, enhancing the learning experience.

Specific Engine Brands & Free Resources

Free small engine repair course PDFs frequently focus on popular brands. Tecumseh manuals are widely available online, covering lawnmowers and snowblowers. Briggs & Stratton offers extensive documentation, including parts lists and service guides. Honda engine service manuals provide detailed repair procedures for their reliable engines.

Websites dedicated to these brands often host free repair resources. Online forums provide brand-specific troubleshooting advice from experienced users. Manufacturer websites frequently offer downloadable manuals and diagrams. Accessing these resources streamlines the repair process, offering targeted information for specific engine models.

Tecumseh Engine Repair PDFs

Tecumseh engine repair PDF manuals are readily accessible online, covering a wide range of outdoor power equipment. These free resources detail carburetor adjustments, ignition system diagnostics, and fuel system repairs. PDFs often include exploded views for parts identification and detailed troubleshooting guides.

Common issues addressed in Tecumseh manuals include starting problems, rough idling, and lack of power. Users can find guides for specific engine models, simplifying the repair process. Downloading these manuals allows for offline access during repairs. Always prioritize safety when working with small engines, following all manual precautions.

Briggs & Stratton Repair Guides

Briggs & Stratton offers extensive free repair guides and PDF manuals for their engines, widely used in lawnmowers and other equipment. These resources cover everything from basic maintenance like oil changes to complex repairs involving the carburetor and ignition system. Detailed diagrams and step-by-step instructions simplify the repair process for both beginners and experienced mechanics.

Finding these guides is easy through the Briggs & Stratton website, often categorized by engine model number. Common repair topics include starting issues, fuel delivery problems, and valve adjustments. Utilizing these PDF guides can save significant money on professional repair services. Remember to always consult the manual for safety guidelines.

Honda Engine Service Manuals

Honda provides detailed service manuals, often available as free PDF downloads, for their range of small engines. These manuals are invaluable for diagnosing and repairing issues with Honda-powered equipment like lawnmowers, generators, and water pumps. Comprehensive sections cover engine overhaul, troubleshooting, and parts diagrams.

Accessing these manuals typically involves visiting the Honda website or authorized dealer sites, searching by engine model number. Key repair areas addressed include valve adjustments, carburetor cleaning, and ignition system maintenance. Proper use of these manuals ensures accurate repairs and extends engine life. Always prioritize safety when working on engines.

Advanced Repair Techniques (Beyond Basic PDFs)

While free PDF courses cover fundamentals, advanced repairs demand specialized knowledge. Techniques like valve seat grinding, cylinder honing, and precision engine balancing require hands-on experience and dedicated training. These procedures often necessitate specialized tools not covered in basic guides.

Beyond manuals, consider advanced online courses or workshops for in-depth instruction. Mastering these skills extends engine lifespan and improves performance. Proper execution prevents further damage and ensures optimal operation. Remember, complex repairs may require professional assistance for safety and accuracy.

Valve Adjustments

Proper valve adjustment is crucial for optimal small engine performance. Incorrect clearances lead to reduced power, poor fuel efficiency, and potential engine damage. Free resources often demonstrate the process, emphasizing the importance of following manufacturer specifications. Typically, this involves removing the valve cover and using feeler gauges to measure clearances.

Adjustments are made using shims or threaded adjusters. Precise settings ensure proper valve timing, maximizing combustion efficiency. Always consult the engine’s service manual for specific procedures and torque values. Incorrect adjustments can cause significant engine problems, so careful attention to detail is essential.

Piston & Cylinder Replacement

Piston and cylinder replacement is a more complex repair, often required after significant engine wear or damage. Free online courses and PDF guides can illustrate the process, but require mechanical aptitude. Typically, this involves disassembling the engine, removing the connecting rod, and extracting the piston.

Cylinder inspection for scoring or wear is vital. Proper piston ring installation and cylinder honing are crucial for sealing and compression. Torque specifications must be strictly followed during reassembly. Resources emphasize the need for specialized tools and careful attention to detail to avoid engine failure.

Governor Repair

Governor repair focuses on maintaining consistent engine speed under varying loads. Free PDF guides detail governor types – mechanical and electronic – and their functions. Troubleshooting often involves checking linkages, springs, and the governor arm for proper movement and adjustment.

Online resources demonstrate how to clean and lubricate governor components. Incorrect governor settings can cause surging or stalling. Detailed manuals emphasize the importance of precise adjustments, often using specialized tools. Successful repair ensures stable engine operation and prevents damage from overspeeding, making it a vital skill.

Staying Updated with Repair Information

Small engine technology evolves, necessitating continuous learning. Online forums and communities, often linked within free PDF course resources, provide platforms for sharing experiences and solutions. Industry blogs and websites offer insights into new diagnostic techniques and repair procedures.

Regularly checking manufacturer websites for updated service bulletins is crucial. Subscribing to relevant newsletters delivers the latest information directly. Participating in online discussions fosters a collaborative learning environment. Staying current ensures effective repairs and adaptation to emerging technologies within the small engine field.

Online Forums & Communities

Engaging with online forums and communities is invaluable for small engine repair enthusiasts. These platforms, often recommended alongside free PDF courses, offer a space to ask questions, share knowledge, and troubleshoot problems. Dedicated forums exist for specific engine brands like Briggs & Stratton and Tecumseh, providing targeted support.

Active participation allows learning from experienced technicians and hobbyists. Sharing repair experiences contributes to a collective knowledge base. Searching archived discussions can reveal solutions to common issues. These communities supplement PDF learning, offering practical advice and real-world insights.

Industry Blogs & Websites

Complementing free small engine repair course PDFs, numerous industry blogs and websites provide current information and detailed guides. These resources often feature articles on diagnostic techniques, repair procedures, and emerging technologies; Many websites offer troubleshooting tips for common engine problems, supplementing the knowledge gained from PDF manuals.

Reputable blogs frequently review new tools and equipment, aiding informed purchasing decisions. Staying updated with these platforms ensures access to the latest repair methods. They often link to official manufacturer resources and free service manuals, enhancing the learning experience. Regular blog reading keeps skills sharp and knowledge current.

New Technologies in Small Engines

Modern small engines increasingly incorporate electronic fuel injection (EFI), advanced ignition systems, and sophisticated diagnostic capabilities. While traditional repair PDFs cover basic carburation, understanding these new technologies requires supplemental learning. Free online resources and manufacturer websites are crucial for staying current.

EFI systems demand specialized diagnostic tools and software, often beyond the scope of basic PDF guides. New engine designs prioritize fuel efficiency and reduced emissions, necessitating updated repair knowledge. Technicians must adapt to computerized controls and data analysis. Continuous learning through blogs and forums is vital for effective repair.