Semi-trucks‚ vital to American roads‚ logged over 500 billion miles in 2022‚ showcasing the prevalence of these vehicles․ These transmissions blend automated and manual elements․

Understanding these systems requires acknowledging their historical evolution and current applications‚ particularly within the heavy-duty trucking industry‚ offering a unique driving experience․

What is a Semi-Manual Transmission?

Semi-manual transmissions represent a fascinating intersection of traditional manual gearboxes and automated technology‚ offering drivers a unique blend of control and convenience․ Unlike fully automatic transmissions‚ these systems don’t entirely remove the driver from the shifting process‚ but significantly reduce the physical demands․

Essentially‚ a semi-manual transmission utilizes automated mechanisms to operate the clutch and execute gear changes‚ relieving the driver of constant clutch pedal engagement and gear lever manipulation․ However‚ the driver typically retains some level of control‚ often through buttons or a simplified shift selector․

These systems detect the optimal gear based on factors like vehicle speed‚ engine load‚ and throttle position‚ then automatically perform the shift․ This contrasts with a traditional manual where the driver handles all aspects of the shifting process․ The mechanics‚ while complex in execution‚ are fundamentally simple‚ automating tasks previously done manually․

Historical Development of Semi-Manual Systems

The evolution of semi-manual transmissions traces back to efforts to enhance driving efficiency and reduce driver fatigue․ Initially‚ the focus was on automating clutch operation‚ with early iterations appearing in racing applications during the 1990s‚ notably with Sequential Manual Gearboxes (SMGs)․ These systems aimed to provide faster‚ more consistent shifts for competitive advantage․

As technology advanced‚ Automated Manual Transmissions (AMTs) emerged‚ offering a more accessible form of automation for commercial vehicles․ These early AMTs‚ while improving efficiency‚ often faced criticism for their jerky shifting characteristics․

The development of Dual-Clutch Transmissions (DCTs) marked a significant leap forward‚ providing smoother and quicker gear changes․ While initially expensive‚ DCTs gained traction in high-performance cars and‚ increasingly‚ in heavy-duty trucks‚ driven by demands for fuel efficiency and driver comfort․ Today‚ advancements like SpeedShifting and SmartShifting continue to refine these systems․

How Semi-Manual Transmissions Work

Semi-manual systems utilize automated mechanisms to manage clutch engagement and gear selection‚ yet retain some driver control․ These systems detect optimal gear choices․

The Electronic Control Unit (ECU) plays a crucial role in coordinating these actions‚ optimizing performance and efficiency․

The Role of the Clutch in Semi-Manual Systems

The clutch remains a fundamental component within semi-manual transmissions‚ despite the automation of shifting processes․ Unlike fully automatic systems‚ semi-manual transmissions don’t entirely eliminate the need for clutch operation; instead‚ they automate its engagement and disengagement․

In Automated Manual Transmissions (AMTs)‚ actuators controlled by the ECU manage the clutch‚ executing shifts without direct driver input on the pedal․ This allows for smoother transitions and reduced driver fatigue․ However‚ the driver often retains the ability to override the system and manually control the clutch when needed‚ providing a degree of control not found in traditional automatics․

Even in more advanced Dual-Clutch Transmissions (DCTs)‚ two separate clutches are utilized – one for odd gears and one for even gears – to pre-select the next gear‚ minimizing interruption during shifts․ The precise timing and coordination of these clutches are managed electronically‚ contributing to the system’s efficiency and responsiveness․ Essentially‚ the clutch in a semi-manual system is not obsolete‚ but rather intelligently managed․

Automated Shifting Mechanisms

Automated shifting mechanisms represent the core innovation within semi-manual transmissions‚ bridging the gap between traditional manual gearboxes and fully automatic systems․ These mechanisms utilize a network of actuators‚ sensors‚ and a sophisticated Electronic Control Unit (ECU) to execute gear changes without direct driver intervention on a traditional shift lever․

In Automated Manual Transmissions (AMTs)‚ actuators physically operate the shift forks and clutch‚ selecting the appropriate gear based on vehicle speed‚ engine load‚ and driver demand․ Dual-Clutch Transmissions (DCTs) employ a more complex system‚ utilizing two separate clutches and pre-selecting the next gear for near-instantaneous shifts․

These systems fundamentally simplify operation‚ reducing driver fatigue and potentially improving fuel efficiency․ The mechanics‚ while complex in execution‚ are based on the principles of a standard manual transmission‚ but the ‘work’ of shifting is handled by the automated components‚ offering a blend of control and convenience․

The ECU’s Role in Gear Selection

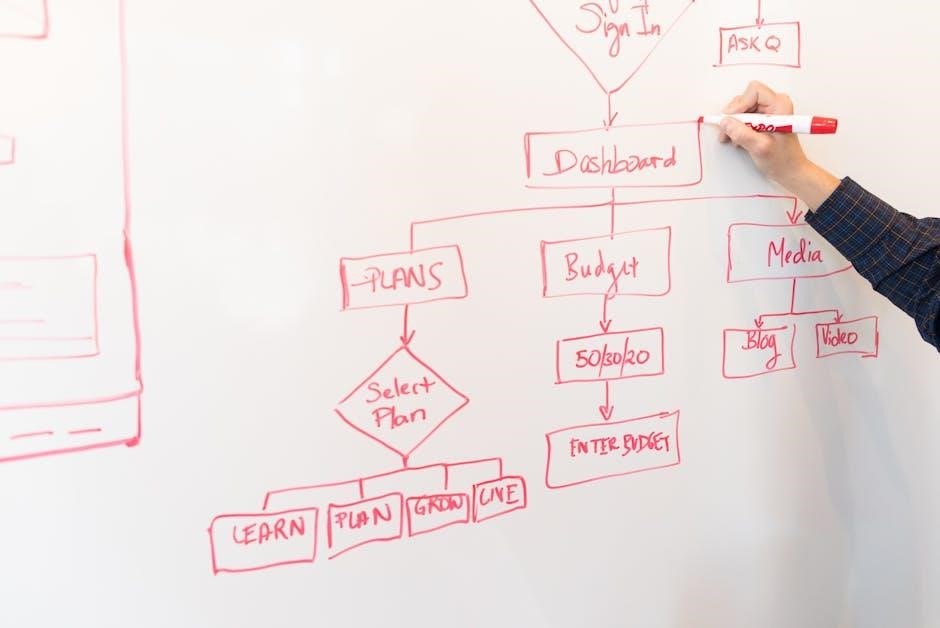

The Electronic Control Unit (ECU) serves as the ‘brain’ of a semi-manual transmission‚ orchestrating gear selection based on a multitude of real-time data inputs․ It constantly monitors parameters like vehicle speed‚ engine RPM‚ throttle position‚ and even road grade to determine the optimal gear for any given driving situation․

The ECU utilizes pre-programmed algorithms and shift maps‚ refined through extensive testing‚ to anticipate driver needs and execute smooth‚ efficient gear changes․ In AMTs‚ it directly controls the actuators responsible for clutch engagement and gear shifting․ With DCTs‚ the ECU manages both clutch operations and gear pre-selection․

Furthermore‚ modern ECUs often incorporate ‘SmartShifting’ or similar technologies‚ learning driver preferences and adapting shift points for personalized performance․ This intelligent control maximizes fuel economy and minimizes stress on the drivetrain‚ enhancing the overall driving experience․

Types of Semi-Manual Transmissions

Semi-manual transmissions encompass diverse technologies‚ including Automated Manual Transmissions (AMTs)‚ Dual-Clutch Transmissions (DCTs) commonly found in semi-trucks‚ and Sequential Manual Gearboxes (SMGs) utilized in racing․

Automated Manual Transmissions (AMTs)

Automated Manual Transmissions (AMTs) represent a significant step towards driver assistance in heavy-duty vehicles․ Unlike traditional manual transmissions requiring direct driver input for clutch operation and gear changes‚ AMTs automate these processes․ Essentially‚ an AMT retains the mechanical layout of a standard manual gearbox but incorporates actuators and a control system – typically an Electronic Control Unit (ECU) – to manage shifting․

These systems detect the optimal gear based on factors like vehicle speed‚ engine load‚ and throttle position․ The truck then automatically shifts gears‚ relieving the driver of constant clutch and shifter engagement; This technology simplifies operation‚ particularly in demanding conditions like stop-and-go traffic or hilly terrain․ With an AMT‚ the truck intelligently determines the appropriate gear and executes the shift‚ enhancing efficiency and reducing driver fatigue․ They are a popular choice for fleets seeking to optimize fuel economy and driver comfort․

Dual-Clutch Transmissions (DCTs) in Semi-Trucks

Dual-Clutch Transmissions (DCTs) represent a more sophisticated approach to automated shifting in semi-trucks‚ offering performance advantages over traditional AMTs․ Unlike AMTs which use a single clutch‚ DCTs employ two separate clutches – one for odd-numbered gears and one for even-numbered gears․ This configuration allows for pre-selection of the next gear‚ resulting in incredibly fast and seamless gear changes․

While currently less common than AMTs in the heavy-duty sector‚ DCTs are gaining traction due to their efficiency and responsiveness․ The overlapping gear changes minimize torque interruption‚ leading to smoother acceleration and improved fuel economy․ This technology is particularly beneficial in applications demanding quick shifts and consistent power delivery․ Though more complex and typically more expensive than AMTs‚ DCTs provide a premium driving experience and enhanced operational capabilities for semi-trucks․

Sequential Manual Gearboxes (SMGs) ⎻ Racing Applications

Sequential Manual Gearboxes (SMGs)‚ a staple in the world of racecars for years‚ represent a highly specialized form of semi-automatic transmission․ Unlike traditional manual transmissions with a shift pattern‚ SMGs allow drivers to select gears sequentially – up or down – using paddles or a lever․ This streamlined system drastically reduces shift times‚ crucial for competitive racing․

While not widely adopted in standard semi-truck operations due to their complexity and cost‚ SMGs demonstrate the potential of automated manual systems․ They require precise control and are optimized for performance rather than everyday hauling․ The focus is on maximizing acceleration and minimizing gear change disruption․ Though less practical for commercial trucking‚ SMGs showcase the evolution of semi-automatic technology and its roots in high-performance driving environments․

Semi-Manual Transmissions in Semi-Trucks

Semi trucks utilize both manual and automated transmissions‚ with compatibility varying by manufacturer and intended use․ Automated systems handle clutch and gear changes․

These systems are increasingly common‚ impacting fuel efficiency and driver workload within the trucking industry․

Advantages of Manual vs․ Automated in Heavy Duty Vehicles

Manual transmissions in semi-trucks traditionally offered drivers greater control and a direct connection to the vehicle‚ requiring skilled operation for optimal performance․ Mastering shifting techniques‚ as emphasized in recent guidance‚ becomes crucial for efficiency․

However‚ automated manual transmissions (AMTs) are gaining prominence‚ detecting the appropriate gear and shifting automatically‚ reducing driver fatigue on long hauls․ This automation enhances fuel efficiency‚ a key consideration given the distances covered – over 500 billion miles logged by these vehicles in 2022 alone․

While manual systems provide a tactile experience‚ AMTs minimize wear and tear‚ potentially lowering maintenance costs․ The choice depends on driver preference‚ operational needs‚ and the specific demands of the trucking application․ Ultimately‚ both options have their place in the evolving landscape of heavy-duty transportation․

Compatibility with Different Semi-Truck Manufacturers

Semi-truck manufacturers are increasingly offering both manual and automated manual transmission options‚ though compatibility varies significantly between brands and models․ Checking transmission compatibility with your intended use is crucial before making a purchase․

Leading manufacturers integrate these systems differently‚ impacting factors like gear ratios and overall performance․ Some prioritize AMTs for long-haul efficiency‚ while others retain manual options for drivers who prefer direct control․

Understanding these nuances requires researching specific truck configurations and consulting with dealerships․ The mechanics‚ while fundamentally simple‚ are adapted to each manufacturer’s engineering standards․ Ensuring seamless integration is vital for maximizing the benefits of either transmission type‚ given the vehicles’ extensive mileage – exceeding 500 billion miles in 2022․

Fuel Efficiency and Semi-Manual Transmissions

Semi-manual transmissions‚ particularly Automated Manual Transmissions (AMTs)‚ are often touted for improved fuel efficiency in heavy-duty trucking․ These systems optimize gear selection‚ maintaining the engine within its most efficient operating range‚ leading to reduced fuel consumption․

By automating the shifting process‚ AMTs minimize wasted energy from suboptimal gear choices‚ a common issue with purely manual operation․ This is especially beneficial on long hauls‚ where even small improvements in fuel economy translate to significant cost savings‚ given the 500+ billion miles logged by these vehicles in 2022․

However‚ achieving optimal fuel efficiency also depends on driver technique and load conditions․ SmartShifting and SpeedShifting technologies further enhance these benefits‚ contributing to a greener and more economical transportation sector․

Advanced Features in Semi-Manual Systems

Semi-manual systems now incorporate SpeedShifting for rapid transitions between the highest gears‚ and SmartShifting‚ combining speed with intelligent gear selection for optimal performance․

SpeedShifting Technology

SpeedShifting represents a significant advancement within semi-manual transmission systems‚ specifically designed to enhance efficiency during highway cruising․ This technology focuses on optimizing gear changes within the highest range of gears – typically the 10th‚ 11th‚ and 12th – commonly used for sustained high-speed travel․

The core principle behind SpeedShifting is to minimize the time spent transitioning between these gears․ By enabling exceptionally rapid shifts‚ the technology reduces RPM drop during changes‚ maintaining momentum and ultimately improving fuel economy․ This is particularly beneficial for long-haul trucking‚ where consistent speed and fuel efficiency are paramount․

Drivers experience smoother acceleration and reduced driver fatigue as the system handles the complexities of quick gear selection․ It’s a feature geared towards maximizing productivity and minimizing operational costs in the demanding world of commercial transportation‚ offering a tangible benefit on the open road․

SmartShifting Technology

SmartShifting technology builds upon the foundation of automated semi-manual transmissions‚ offering a more intelligent and adaptive approach to gear selection․ Unlike traditional automated systems‚ SmartShifting doesn’t simply react to vehicle speed and load; it actively anticipates driving conditions and optimizes shifts accordingly․

This advanced system integrates data from various sensors‚ including engine load‚ road grade‚ and even predictive cruise control information‚ to determine the most efficient gear for any given situation․ It combines the benefits of rapid shifting‚ similar to SpeedShifting‚ with a broader focus on overall efficiency and driver comfort․

The result is a smoother‚ more responsive driving experience‚ reduced wear and tear on the drivetrain‚ and improved fuel economy․ SmartShifting represents a step towards truly autonomous transmission control‚ enhancing both productivity and safety for long-haul truckers․

Learning to Operate a Semi-Manual Transmission

Mastering a semi-manual transmission requires practice and feeling; it’s not just about the lever‚ but understanding how the truck responds to each shift․

Tips for Mastering Shifting Techniques

Successfully operating a semi-manual transmission hinges on developing a keen sense of feel and timing․ Begin by focusing on smooth clutch engagement and disengagement‚ coordinating it precisely with gear selection․ Listen attentively to the engine; it will communicate when a shift is necessary‚ guiding you towards optimal performance․

Anticipate road conditions and traffic flow to proactively select the appropriate gear‚ minimizing unnecessary shifting․ Practice consistent shifting patterns‚ aiming for fluid transitions between gears․ Avoid abrupt movements‚ as they can lead to jerking and increased wear on the components․ Remember that automated manual transmissions (AMTs) still require driver input for certain situations․

Gradually increase speed and complexity as your confidence grows‚ always prioritizing smooth and controlled shifts․ Consistent practice is paramount; the more time spent behind the wheel‚ the more intuitive the process will become․ Don’t hesitate to seek guidance from experienced drivers who can offer valuable insights and feedback․

Maintenance and Troubleshooting

Regular maintenance is crucial for ensuring the longevity and reliability of a semi-manual transmission․ Periodically inspect the clutch for signs of wear‚ such as slippage or difficulty engaging․ Check fluid levels regularly‚ topping off as needed with the manufacturer’s recommended lubricant․ Inspect shift linkages for proper adjustment and lubrication‚ addressing any binding or looseness promptly․

If experiencing shifting difficulties‚ begin by verifying proper clutch adjustment․ Unusual noises during operation may indicate internal component issues requiring professional attention․ Diagnostic tools can help pinpoint electrical or sensor malfunctions within the ECU․ Address any warning lights immediately‚ as they often signal underlying problems․

Remember that preventative maintenance is far more cost-effective than extensive repairs․ Consult the vehicle’s service manual for specific maintenance intervals and procedures․ A well-maintained transmission contributes significantly to overall vehicle efficiency and safety․